Bentley Continental GT V8 Twin-Turbo: Paint Correction

It seems hard to believe that the Bentley Continental GT has been on our roads for all of 17 years. Not only is it now firmly established in the Grand Tourer range, it would also be no exaggeration to suggest it is even the leading candidate for class leader too.

Eyebrows were raised when Volkswagen acquired Bentley in 1998 and when the GT finally hit showrooms in 2003 it would become the first Bentley to be mass-produced. Bentley’s aim was to satisfy a whole new segment of potential buyers with something compact and affordable, but still in-keeping with the famous Bentley tradition. They hit the nail on the head and 6 months ahead of delivery, Bentley had already secured over 3000 deposits for this exciting new Grand Tourer.

Fast forward to 2011 and the Continental had evolved into its second generation. In 2012, power now came from a twin-turbo 4L V8 courtesy of Audi, the Bentley offered mass appeal to a much wider audience. Power, sophistication, class and even to a certain degree, economy. Fuel consumption had improved by 40% when compared to its 6L W12 predecessor.

Wheels & Body De-Contamination

This 2014 example finished in black rumbled (quite literally) into our detailing studio at Brands Hatch for a Paint Correction Service. It’s that particularly damp, cold and wet time of year and on the journey to us alone, it was clear to see the paintwork was covered in contaminants collected along the way.

Mud, rain splatter, pollen, leaves, bird mess and a lot of swirling marred the paint and trim heavily. The Bentley was in need of a very thorough pre-wash prior to re-entering our studio for the paint to be focused on.

Although the black Bentley was far from looking its shiny best upon arrival, this was definitely one of those detailing projects which we had great anticipation to deliver a fantastic gallery of before and after creatives from.

The 21-inch 7 spoke diamond turned alloy wheels were heavily soiled in corrosive brake dust so it was imperative they were treated accordingly at the pre-wash stage.

Gtechniq W6 Iron Fall Out is formulated to remove contaminants safely and is applied to the wheels. The brake dust and fallout dissolve quickly under the pressure of the high-cling gel formula and allow particles to be loosened, then jet washed off with the pressure washer. As ferrous particles dissolve, purple patches begin to appear on the wheels and ground, showing the Fall Out remover actively working. After a few minutes (and ensuring the product does not dry), all remains can then be blasted away.

Ahead of the main wash process, the GT’s pre-wash continues using Ultimate Snow Foam. This is applied using a Kranzle K-1152 pressure washer. Covering the coupe in a thick white lather, it clings to the panels, working away at harder to reach areas such as the fuel filler cap and tailpipe. Bigger particles of dirt and grit are also lifted – removing as much of the contaminants at this stage greatly reduces the chance of harming the paintwork once the contact washing begins.

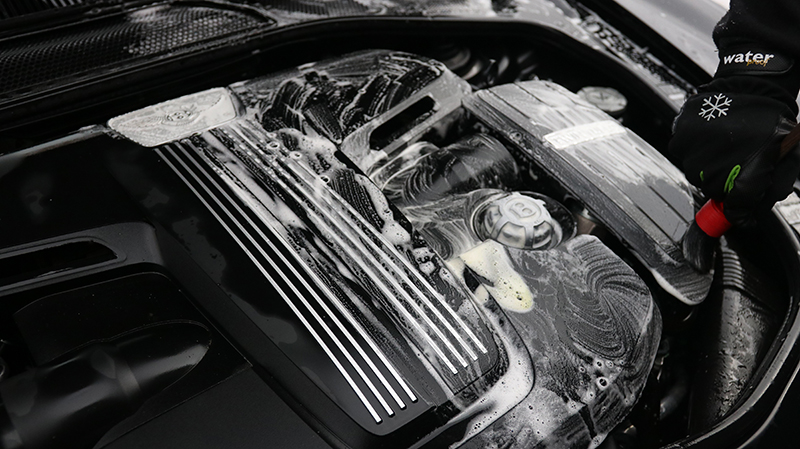

Underneath the bonnet, the imposing V8 engine has generated plenty of grease and grime around the engine bay. Using a Swisswax Detail Brush and Bilt-Hamber Surfex HD (diluted at a ratio of five parts water to one part product), the bay is carefully treated all over. Surfex is a biodegradable non-toxic cleaner and uses no solvents, so it is ideal for attacking the dirt without being too aggressive on the engine itself. It’s an impressively gleaming sight once fully cleaned.

Inspecting, correcting & refining

Once the Bentley had been washed and dried it was time to begin work on that black paintwork. Damage to paint is so often more apparent on a vehicle with a darker finish and the GT was no exception. The inspection determined that there were deep scratches on the bonnet and in terms of light scratches and swirls, there were plenty. Every panel on the Bentley was marred.

The owner of the GT had advised us that regrettably, he had paid a few visits to a local hand wash service and the deep scratches mentioned were most likely collected there, thanks to a drying technique using a water blade squeegee.

The dreaded water blade squeegee. As we know, a budget car wash visit will most likely not even get you a pre-wash prior to the wash process, so the chances of fragments of dirt still being present on your bodywork are highly likely. It is at this point where our friends at the car wash reach for the water blade squeegee to wipe off all the standing water on the car and in doing so, (you’ve guessed it) scrape any remaining dirt, dust or grit across the paintwork in the process. If you’re lucky you’ll escape with light scratches at best. The mere thought of this is enough to make any car care enthusiast shudder!

Back to the Bentley, and the deeper scratches on the bonnet need to be wet sanded using a Rupes X-Cut Abrasive on a Foam Interface Pad, and a Rupes LHR 15ES machine polisher. Due to the nature of the bonnet scratches, wet sanding was deemed the most effective and efficient solution for removal.

The remainder of the paint correction (including the earlier wet sanded area) is carried out with Koch-Chemie Heavy Cut H8.02 on a RUPES Green Polishing Pad.

With the paintwork now corrected all over, it was time for the refinement stage. Our pro-detailer applied Menzerna Super Finish Plus 3800 on a RUPES Yellow Foam Polishing Pad, again using variations of Rupes Machine Polishers depending on the size of panel being treated. For the smaller section a RUPES LHR 75E Mini.

Leaving ultra-protected

The Bentley’s paintwork and trim are treated with a Gtechniq Panel Wipe which readies the surface for the final protective coating by removing any remaining silicone residues or polish. With the surface now completely de-contaminated, the final protective sealant process could now begin in the form of Kamikaze Collection’s ENREI.

The flagship two-step system begins with the application of the base coat, where, a chemical reaction takes place and locks into the vehicle’s clearcoat. This effectively provides a platform for the No.2 top coat to cling onto with maximum effect once applied.

Once hardened and cured, the resulting finish is ultra-smooth, with an organic/inorganic hybrid layer now in place. Kamikaze’s application methods are very specific in order to achieve the absolute best results and the same goes for the sensitivity of time for curing. ENREI Coat is available as a service with us here at Ultimate Finish or via the Kamikaze Collection trained and certified detailer network.

Once cured, all that is left to do is sit back and soak up the fantastic finish. Every panel on the Bentley was now shimmering, exactly how it should be.

Featured Products Used

Gtechniq W6 Iron & General Fall out Remover £5.95

- Dissolves fallout & brake dust quickly

- High-cling gel formula

- Will not remove wax or sealants

Bilt-Hamber Surfex HD £10.50

- Biodegradable, non-toxic cleaner

- Removes tough grease and oil-based contamination

- Can be used neat for harder grime or diluted for lighter cleaning duties

Swisswax Detail Brush £12.00

- Ideal for cleaning inaccessible areas

- Removes excess grime

- Soft Bristles

X-Cut Foam Interface Pad £9.95

- For use with RUPES X-Cut Abrasives

- Suitable for wet sanding

- 125mm pad

RUPES Foam Medium Polishing Pad

- Medium density foam machine polishing pad

- Removes moderate to light swirls, scratches & blemishes

- Suitable for all types of automotive paintwork

Want your vehicle’s appearance cosmetically enhanced or protected? To discuss the most appropriate detailing treatment call 01474 360 360 or complete the online enquiry form here. We provide a bespoke, no-obligation quote via email.

Shop The World’s Best Car Care Products – Ultimate Finish

Award-Winning Detailing – UF Studio