Nissan Skyline GT-R (R33) – Restoring A Japanese Classic (Part 1)

Aimed at the luxury sport market, the Nissan Skyline has long been popular with Japanese performance car enthusiasts. Immortalised in Playstation’s Grand Turismo, the Skyline GT-R captured the imagination of a new generation and arguably became an automotive legend. The R33 was introduced in 1995 replacing the R32 and although it retained much of the technical characteristics of the previous model, including all-wheel drive and all-wheel steering, the new model featured some significant differences which would impact the overall balance, handling and performance of the car. The new model was four inches longer and an inch wider. Air intake scoops were repositioned and enlarged to allow for improve engine cooling and aerodynamics. Various weight saving measures were employed, including the hollowing out of side door beams, whilst front and rear aluminium stabiliser bars increased chassis rigidity. New plastics for headlights and fuel tank (which had also been repositioned for improved balance and handling) along with a number of other tweaks saw the GT-R shave 23 seconds off its lap time at the Nurburgring.

Keen to own an original, uncustomised Skyline, this R33 GT-R was purchased through a Japanese import specialist and brought into the UK in March of this year, with full Japanese service history and around 45,000 miles on the clock. Since then, the owner has spent a not insignificant amount of time and money having it mechanically restored by Japanese specialists Abbey Motorsport and it now produces around 320 bhp as opposed to the standard 280bhp. The interior has been refurbished in black Nappa leather and various panels on the interior have been replaced. Looking to have the cosmetic appearance enhanced, the owner booked the Skyline into UF’s Brands Hatch studio for a number of detailing services including Paint Correction and protection with Japanese brand, Kamikaze Collection’s flagship and most technically advanced ceramic coating, ENREI. Stone chips on the uppermost front grille needed addressing, plus the owner specified protection requirements for the glass, fabric, wheels and newly refurbished leather interior.

Prior to the detailing work, a thorough appraisal was carried out to determine the condition of the paintwork. As a result of the appraisal it was decided to repaint the front and rear bumpers along with the boot spoiler where the clear coat had begun to degrade.

Machine polishing produces excellent results by removing a very small amount (microns) of clear coat. On parts of the GTR, particularly the rear boot spoiler, the clear coat had completely degraded making it impossible to machine polish. – Matt Back, UF Detailing Studio

UF provide a concierge service for any body shop work that is required, following the whole process from preparation through to final inspection to ensure the quality of paintwork meets their exacting standards. In this instance, the rear spoiler, the front and back bumpers required stripping back and repainting. At the same time, the three front aluminium mesh grilles supplied by the owner would be fitted. The badges and stickers looked tired and stained and would contrast starkly with the restored appearance of the Skyline. As such the owner sourced genuine Nissan items for fitment once the paintwork was complete.

It was a comprehensive package the customer had spec’d, so we knew the Skyline was going to be in our care for several days. However, once completed, it was going to look fantastic. The original badges and stickers would have looked out of place next to the pristine paintwork, so it made sense to fit new ones which would be more in keeping with the cosmetic restoration. – Matt Back, UF Detailing Studio

Once back from the body shop, decontamination of the Skyline began with an application of Bilt-Hamber Korrosol, a dedicated iron particle remover. Sprayed on, Korrosol’s active ingredient shrinks iron particles, causing them to break their bond with the underlying substrate and allowing them to be easily rinsed away. Whilst Korrosol was working to neutralise the iron fallout, an initial application of Ultimate Snow Foam was sprayed over the top. Applied using a foam lance connected to a Kranzle K-1152 TST pressure washer, Ultimate Snow Foam creates a thick, clinging foam that dwells, even on vertical surfaces.

Korrosol and Ultimate Snow Foam are examples of non-contact methods of decontamination. Typically paintwork damage occurs during the wash process, when dirt caught in the wash mitt gets dragged over the paintwork. Korrosol is effective at eliminating iron contamination, caused by pads shredding when the brakes are applied. Ultimate Snow Foam lifts any larger particles of dirt away from the surface and encapsulates them within the foam. The contamination can then be rinsed away safely helping prevent swirls and scratches. – Matt Back, UF Detailing Studio

Once the Skyline had been rinsed, the panels and under the wheel arches were degreased using Bilt-Hamber Surfex-HD, breaking down road grime and diesel splatters which may cause staining and interfere with the final sealant. The wheels were cleaned thoroughly back to front with the aid of Wheel Woolies. Rinsed again, the Skyline was covered once more with Ultimate Snow Foam to provide lubrication for a clay mitt. The mitt works in the way of a traditional clay bar, shearing stubbornly bonded particles away from the paintwork and leaving the surface perfectly smooth to the touch.

After pressure-washing away the foam, the Skyline was washed using the Two Bucket Method. This uses separate buckets for Wash water and Rinse water, both buckets contain Grit Guards in the bottom for the wash mitt to be brushed across. The mitt is dunked into the Wash bucket, loaded with soapy wash solution (in this instance, Nanolex Pure Shampoo) and then a section of the car is washed. The mitt is then dunked into the Rinse Bucket which contains fresh water, the mitt brushed over the Grit Guard, releasing dirt and contamination which sinks to the bottom of the bucket, the Grit Guard helping keep it there. The process is repeated until the car is clean.

Once thoroughly clean, the soapy residue was rinsed away before an Aqua Gleam De-ionising Water Filter was attached in-line to deliver a final, pure water rinse. The Skyline was then brought into the studio. Here, using a steamer to loosen the bond, the stickers and the badges were removed.

A BigBoi BlowR Pro touchless air dryer was used to chase water off the surfaces and force droplets out from tight areas. This prevents drips escaping at a later date and running down the panels during the coating application – an event that can interfere with the curing process.

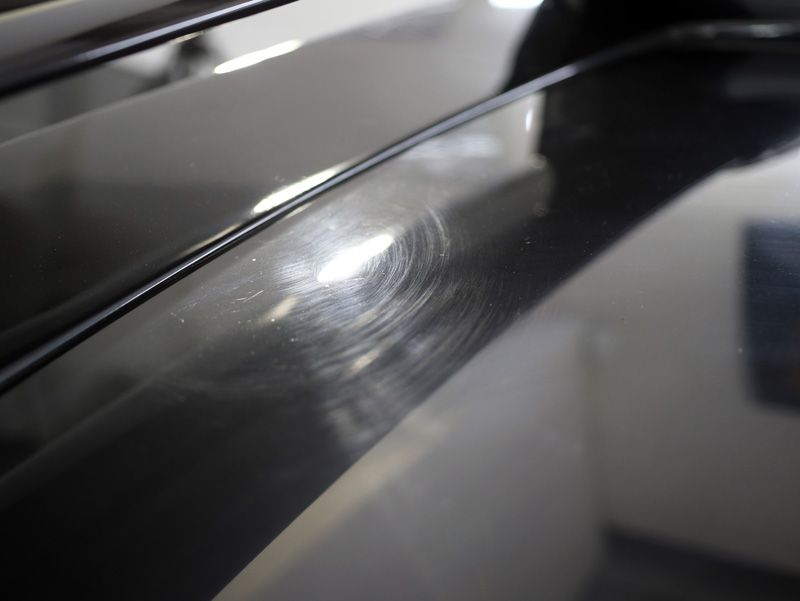

The panels were inspected under high-intensity lighting and found to be severely swirled. In addition, many random deep scratches (RDS) were visible.

Using a PosiTest DFT Combo paint depth gauge, readings were taken over multiple points on each panel to determine the thickness of the paint and clear coat covering.

As Japanese paint is typically quite soft it cuts back quite easily. It’s important therefore, to determine how much there is to begin with to ensure no inadvertent damage occurs. To correct the paintwork, I selected a Kamikaze Collection pad as it’s been designed with Japanese automotive paintwork in mind. – Matt Back, UF Detailing Studio

Kamikaze Collection Banzai Dynamics Polishing Pads feature a nippled surface, using Dot Point Polishing Technology to maintain improved air circulation. This is particularly important when working on soft paint as it dissipates heat build-up, reducing the opportunity for marring the paintwork. The Banzai Dynamics pad was used on a RUPES Duetto dual action polisher with Menzerna Heavy Cut 400 compound. This combination also worked well on the newly painted areas, which as requested had been left unfinished by the body shop.

A RUPES Nano iBrid, a compact and lightweight multi-action hand held polisher was used to restore the damage along the sills, door pillars and other narrow areas. The Nano iBrid can be operated either as a standard corded tool, or as a cordless, battery powered polisher. It also has the option to switch between rotary and dual action depending on the job at hand. In this instance, the lower heat generation of the dual action was preferred.

Refining the paintwork required a soft pad and a fine finishing compound, so a 3M PERFECT-IT III Black Polishing Pad was used with Menzerna Super Finish Plus 3800. A FLEX PE14-2-150 rotary polisher was used, the direct action of the rotary helping to bring out a glossy finish to the Midnight Grey Pearl paintwork.

This worked perfectly to restore the clarity to the paintwork.

With the paintwork now corrected and refined, it was time to turn attention to the protection of the various substrates and the finishing touches that would transform the GTR.

Read about the next stage of this amazing make over in Nissan Skyline GT-R (R33) – Restoring A Japanese Classic (Part 2).

UF Detailing Studio – Award Winning Detailing. Call 0333 800 8004 to discuss your requirements.