In this write-up we will look at the three different types of movement found in electronic detailing machine polishers. Rotary, Dual Action and Direct Drive. This is a fundamental guide to help understand the differences, but we also have detailed write-ups on each movement going into more depth. For now though, this guide is here to help you choose the most suitable machine polisher to suit your specific needs.

Before we break down the different types of machines, it is best to note that the cost of a machine polisher is going to be a big factor in the overall level of both the quality and performance. Like all mechanical items, higher-quality materials, tighter tolerances and additional features all add to a better and more pleasant user experience - this remains the same case with any machine polisher. Even with the most suitable machine polisher, you will not achieve the desired results without many hours of work, and the potential of a broken machine could be costly. This doesn’t mean everyone needs to invest in a £500 professional kit, but if you are intending to work on multiple cars, picking up the cheapest machine polisher you can lay your hands on may not be the best option.

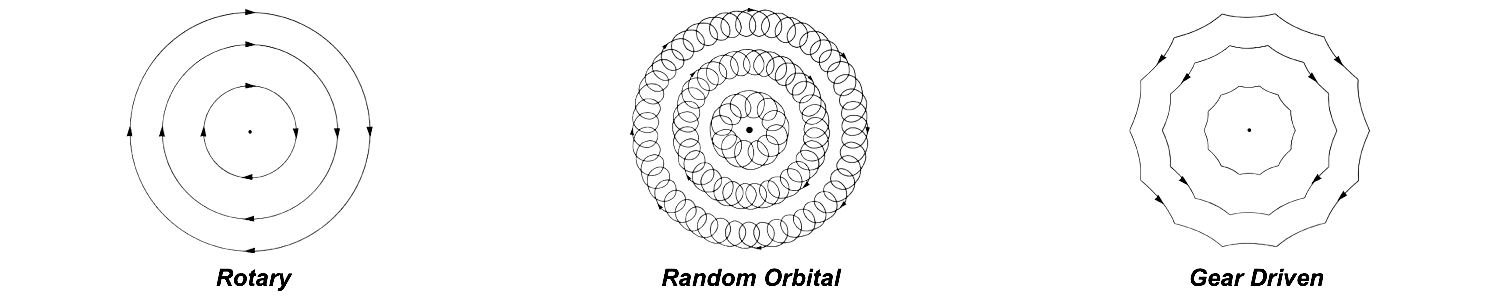

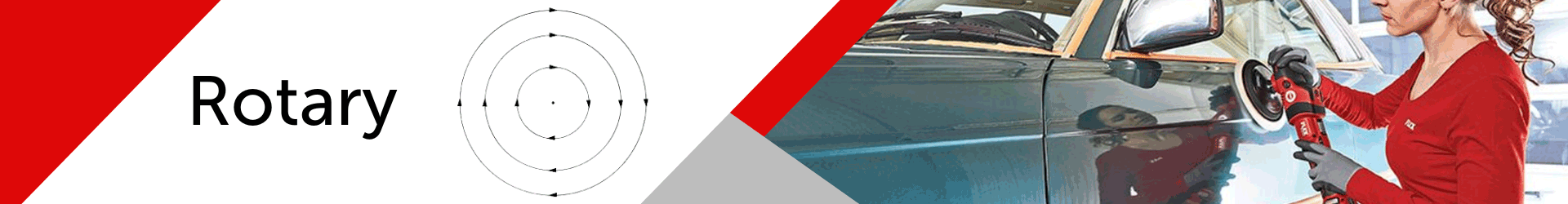

Rotary Polishers

Offering the same action as that of a drill or angle grinder, the backing plate on a Rotary machine polisher spins around on one axis. For detailing purposes this will provide the highest level of “cut” when compared to Dual Action and Direct Drive. Imagine running an abrasive pad and compound over the same fixed point 1000’s of time per minute. This is going to generate quite a bit of heat, softening the paint in the process and allowing the abrasiveness of the pad and compound to remove all the lacquer, potentially. This might sound somewhat alarming, but this would be the worst case scenario. With the correct use of a Rotary polisher they are perfectly safe to use on paintwork and have been used by detailers for many decades. What you have to bear in mind is the potential for error is always there if you happen to get a little heavy-handed. Also, when it comes to the finishing process, side holograms and buffer trails are certainly easier to come by when using a Rotary machine polisher. Such issues are easily fixed, but when time is often money, spending extra hours working on correction can prove costly.

Why choose a Rotary machine polisher in the first place if such issues can arise? Cost is often a major factor. Even though the price of a good quality dual action machine polisher has fallen retrospectively in price in over the years, Rotaries are still the cheapest option. User-technique is a little more difficult to master with a Rotary machine polisher too as they do have a tendency to skip if the pad is not completely flat with the panel. With the right know-how and application, the Rotary system offers all the power required for amazing results. From that perfect final finish to wet sanding, rotary machine polishing is the cheapest package on offer.

Backing plates are interchangeable and give you the range of 25mm to 180mm or more. Most will come with a 125mm as standard and an option for 75mm. Remember though, when changing the backing plate the speeds will start to impact either the cutting levels or pressure on the mechanics inside. Always stick with the manufacturer’s recommendations and you shouldn’t have any issues.

Dual Action Polishers

As it says in the name, dual equals two actions. Dual Action Machine Polishers have two movements on the backing plate. It firstly spins like a Rotary but then also spins around on a counterweight axis. The “throw” of the machine is the distance between the centre point of the backing plate and the centre of the counterweight. A larger throw will give you a larger working area, also making them faster but additionally give a little less control close to the edges. The smaller or tighter the throw the more controlled the machine will be near edges, but the smaller the overall work area. Anything between an 8mm and 15mm throw will be normal and preference of which of the two is better often falls on the user. Anything larger than 15mm would be better suited for large panels such as vans or campers etc. Less than 8mm and we would be looking more at specific sanding machines or smaller backing plate sizes to start with. Backing plates on Dual Action machine polishers should not be swapped unless a purpose-built kit is supplied with an alternative already. The counterweight is designed for a certain weight/speed of backing plate rotation. Anything larger or smaller is going to cause vibration that could potentially result in the machine suffering from broken bearings. Start off with a cheaper Dual Action machine polisher and this will more than likely provide significantly higher base level vibrations, purely because of the cheaper parts used in construction.

Now that we have covered some fundamentals of what the Dual Action machine polisher can offer, you may ask why is this the most commonly chosen movement for so many? Safety. The two movements help to reduce the potential for burning through the paintwork massively. If you apply too much pressure to the polisher during use the second spin of the backing plate, it will likely stop and the cutting power will drastically drop. To get the sweet spot for efficient polishing, it does take a little more practice, but if you aren’t in the magic window you won’t cause unwanted damage unlike a Rotary machine polisher.

For any beginner looking to delve into machine polishing, Dual Actions are certainly the safe bet option. Get used to the machine, start to grow your skill levels, and you will soon be able to deal with even the deepest of scratches. As mentioned on Rotary Polishers, holograms and buffer trails can be an issue, but this is not the case with a Dual Action. They could of course happen under extreme circumstances, but are much, much easier to deal with and are only normally a result of rushing the finishing stage.

Gear Driven Polishers

Providing the best of both worlds, Gear Driven Machine Polishers offer all the power of a Rotary, but with all the safety of a Dual Action. So, why would you not just choose a Gear Driven Polisher in the first place? Two reasons, the weight and cost. Gear Driven machines, as the name describes, contain a geared polishing head. This means the backing plate is not freely spinning compared to that of a dual action, but predictably moving around in a predetermined pattern. What you end up with is a capable machine polisher that will pass over the same spot more frequently when compared to a Dual Action, but not as much as a rotary. More cut, fewer holograms; a real goldilocks story. Gear Driven polishers still make up less than 10% of all machines used by detailers, mainly because of the cost and weight. These are two big factors that will often turn detailers off from switching away from their preferred Dual Action or Rotary. If you already have a machine working effectively, then why switch to a new one for a little extra performance?

Gear Driven isn’t likely to be a machine polisher that a beginner starts with, just because of the cost compared to the other two, you will rarely find a budget version. That said, if you are a beginner with a healthy budget, it presents a great solution. Gear Driven Machine Polishers offer the easiest and smoothest user experience of all three movements. One downside however is the gears do make these machines heavier and over the course of a day you will end up with arms like Arnold Schwarzenegger (possibly an upside) so this is something to bear in mind.

Backing plates are of course not really interchangeable here. This means you are fixed into the normal 125/150mm backing plates, which is easier enough to do the majority of a vehicle, but another machine will likely be needed to get into the smaller areas.

To Summarise:

- Rotary - Cheaper, aggressive cutting power, most versatile

- Dual Action - Midrange price, safest, cheap machines will vibrate and be noisy

- Gear Driven - Most expensive, smoothest, most efficient and heavy

Our recommendation would be to go with a good quality Dual Action machine polisher and practice, practice, practice to get the best results long term.